Dr Charles Kuehmann leads materials engineering at two of the world’s most innovative companies: Tesla and SpaceX. He’s also the owner of an Elan GT5 with a Torqeedo Deep Blue Hybrid drive system. We sat down with him to talk about his electric experience.

You work on electric cars and space travel – what draws you out on the ocean?

My father ran a marina on the Colorado River, so I grew up boating. We were always on the water. I learned to sail during grad school at Northwestern and stayed in the Chicago area for 28 years, boating and sailing on Lake Michigan. But, other than a few charters in the BVI and the Caribbean, my experience was mostly daysailing and powerboating. Now I live in California, and I wanted to take the opportunity to make longer trips and spend whole weekends on the water. It was time to get a bigger boat.

I think every boater has uttered those same words at some point. What did you want in your bigger boat?

I had the idea that I wanted to do electric, so I was looking for a fast, lightweight and efficient hull that still offered decent accommodations for weekends onboard and coastal cruising.

Please adjust your cookie settings using the button below

and enable "Functional Cookies".

Please adjust your cookie settings using the button below

and enable "Functional Cookies".

Please adjust your cookie settings using the button below

and enable "Functional Cookies".

Why did you want to go electric?

I work for Tesla; I know the benefits of electric power. I did a lot of research about the state of the technology and high-power electric drives available in the marine market. There are a lot of people who post in blogs and online forums who say it can’t be done, and it isn’t practical, but there are always naysayers – I’m used to that. I was convinced that it was not only possible but that converting to hybrid-electric could bring a lot of advantages. I wanted to prove it. I chose the 25 kW Deep Blue saildrive system, and since I was already in contact with Torqeedo, I knew precisely which components would be involved in a Deep Blue Hybrid installation, their dimensions and how much they weighed. A sailboat is all about weight and balance - I needed to keep the weight low and as close to the centreline as possible.

“I work for Tesla; I know the benefits of electric power”, says Charles Kuehmann.

What drew you to the Elan GT5?

A lot of homework! As you might suspect, I’m interested in the methods of construction and materials chosen – the Elan GT5 uses the highest quality materials, including structural bulkheads and a laminated hull built with 3D vacuum infusion technology. The hull and the deck are fibreglass and structural closed-cell foam core. It’s a well-built boat, it’s fun to sail, and it has a lot of onboard creature comforts you would typically find in a larger vessel.

I wanted to have the system installed at the factory but Elan didn’t have the capacity to take on the electrification project. I considered buying a different boat but, in the end, I decided to do a refit so I could have the boat and the systems exactly as I wanted. There were moments of frustration, though. We tried to build the boat without the diesel auxiliary but to get the export approved the boat must be certified “seaworthy”. An ocean-going yacht can’t be certified without a motor. Eventually, I accepted that we’d have to put the auxiliary diesel in just so the boat could ship, then remove it once it arrived.

How did you collaborate with Torqeedo? Did you work through a boatyard or refit facility?

Torqeedo supplies the equipment and the technical knowledge, but you need a good boatyard to do the mechanical installation. I found a local outfit in San Diego with expertise in installing high-voltage systems. They helped me with the plans for the modifications.

Okay, you’ve chosen your system and your boat. Your brand-new GT5 is finally delivered to the boatyard – how did the installation go?

I had the information from Torqeedo, but the technical info and exact dimensions of the internal and mechanical spaces of the boat were harder to obtain. Once we got the boat and could measure ourselves, there were a few changes of plan.

What caused the change of plan?

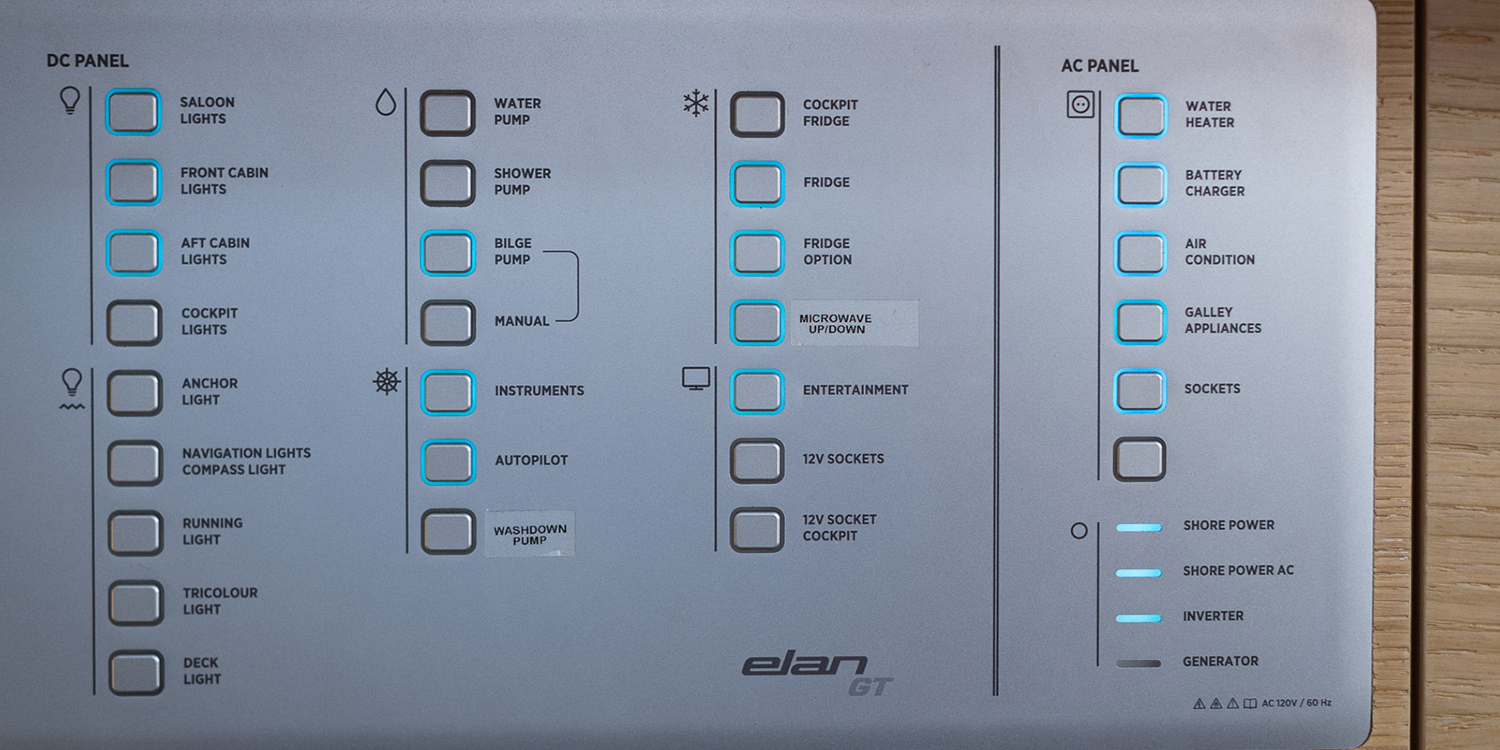

I went with the hybrid system with the diesel generator. Due to its weight, the genset had to be in the centreline. I was hoping to fit both the genset and the motor in the engine compartment but it was a little too tight. We were able to take a little space from under the cabin floor to install the motor. Now, the heaviest components are all installed on the centreline, super-compact, close together and easily accessible. It’s a beautiful installation but it required major surgery on the hull to close up the existing saildrive and cut a new hole for the Deep Blue. The only visible compromise, though, is in the aft cabin. It was a double berth and I converted it to a single berth so I could have really good access to the genset, the electronics the power converters and the electrical panel.

Two 10kWh Deep Blue batteries are installed in the aft cabin for easy access.

Were did you place the batteries?

I chose two 10 kWh batteries because of their smaller footprint. You want to keep the batteries low in the boat, but you can place them almost anywhere without too much trouble. It’s just a matter of running the cables.

Were there other systems changes during the refit?

I probably would have made a lot of systems improvements if I had selected a different yacht, but the Elan has a very modern electrical system with a full array of sensors and remote monitoring straight from the factory. Overall, it’s a very high-tech and well-thought-out boat so it was just a matter of integrating the components into the Deep Blue Hybrid system so they could be powered in a cleaner, more efficient way.

How does the electric saildrive perform?

I really only use it when I’m in the marina where I need a lot of control. With the diesel you have to apply bursts of power before you get any control. Manoeuvring the boat with electric is much smoother. The instant torque and immediate power delivery make the boat very easy to handle.

What’s life onboard like with Deep Blue Hybrid?

Knowing it’s more sustainable is great but what I notice is that it’s convenient. I show up at the dock and my “tank” is full – I don’t have to think about when I’ll go to the fuel dock and fill up. It’s taken care of by the system. Now that I’m cruising and doing overnights, I’ve found I have more power available on the boat than I do when I’m plugged in at the dock. I can run the air conditioning and all the electrical appliances on the boat without ever worrying that I’ll run out of power. The generator runs a half-hour or an hour a day, and I can schedule it.

“Tiha Strela” means “silent lightening” in Slovenian – it can be charged in the harbour.

What did you name your boat?

Elan is a Slovenian company so I went with Tiha Strela, which is Slovenian for “silent lightning”. She’s registered in Mars, California, as a nod to my boss, Elon Musk. Since developing the materials that will allow us to visit our neighbour planet is part of my mission at SpaceX, he wants me to always be thinking about Mars. Now, whether I’m thinking about interplanetary travel for work or cruising out to Catalina on the weekend, my mind is always on Mars.

Do you feel like you accomplished what you set out to do?

I do. Electric and hybrid propulsion for sailboats makes sense. It can be done. It works very well and it makes spending time on the boat much more enjoyable. And, it’s the right thing to do.

Everything under control: Kuehmann cherishes the sustainability of the electric drive system. And enjoys the comfort.

You’re in charge of materials engineering for Tesla and SpaceX, two companies which are redefining their industries. What is and you’re widely considered an expert in computational materials design. What is computational materials design?

Materials engineers aren’t usually tasked with creating the absolute perfect material for the application, they are often developing a material that can be produced reliably, does the job effectively, meets a price point and has the lowest possible impact on people or planet. If a change to a material’s structure increases performance by 10% but it doesn’t transfer heat as well, which might cause the component to fail 0.02% more often, then the engineer has to decide what is more important. Materials design models run simulations that help make those decisions easier.

Electric mobility and advanced materials science are transforming the automotive industry. Do you see that technology transferring to the marine industry?

The marine industry is pretty adept at adopting the newest materials trends, particularly with advanced composites and state-of-the-art adhesives. And, to some degree, in propulsion systems –more lithium-ion batteries are going into boats to power the onboard loads or an electric drive. But, most high-tech materials and systems are being developed outside the marine industry due to the low volumes involved. The most technically advanced yachts are using CFD modelling developed in aviation and many of the same materials and manufacturing methods that came from the aviation and aerospace industries.

Which industries are collaborating most closely and sharing technology in the US?

There is some collaboration between SpaceX and Tesla but the companies are separate and the automotive industry is a high-volume industry – 90 million autos are built worldwide every year – so the volumes and cost structures are really different from aerospace or marine. If I have to generalise, I’d say automotive companies are driving electric vehicle and battery technology and most high-tech materials, models and methods originate or are first commercialized in the aerospace industry. For high-end yachts, you’re free to make the ideal materials and systems selections without worrying about the scale and difficulty of mass production required for building autos, which also have to hit a more competitive price-point. You’re providing the best experience to your owners instead of figuring out how to please millions.

An Electric Life

Kuehmann earned a PhD in Materials Science & Engineering from Northwestern University in 1994. After graduation, he co-founded a company which made several advancements in materials engineering processes and design, and brought new alloys to the market. The business was acquired by a Silicon Valley consumer electronics company and Kuehmann went on to lead their materials engineering team, focusing on aluminium alloys. Kuehmann moved to Tesla and SpaceX in 2015 and is responsible for building the materials engineering teams at both companies.

More information:

Find high-resolution pictures at the: › Torqeedo Dropbox

Find the main catalogue 2020 here: › Catalogue 2020

Relevant Torqeedo Products

“It can be done. And, it’s the right thing to do.”

- Sailboats

- People

- Tech